Equipment which are used in blank production, allows to cut, bend and found sheet metal thickness up to 160 mm, and also process various profiled iron.

FORMING

- maximum width of the flexible sheet, 4500 mm;

- Maximum thickness of bent sheet: when it is bent in a cold state, 80 mm;

when it is bent in the hot condition to 160 mm. - flanging machines for bending flanges.

Forging area:

- hydraulic press with the capacity Q=800 T. S. for forming elliptical elements and spherical heads, as well as parts obtained by hot stamping;

- Pneumatic free forging hammer with mass falling parts up to 400 kg;

pressing equipment for cold forming parts.

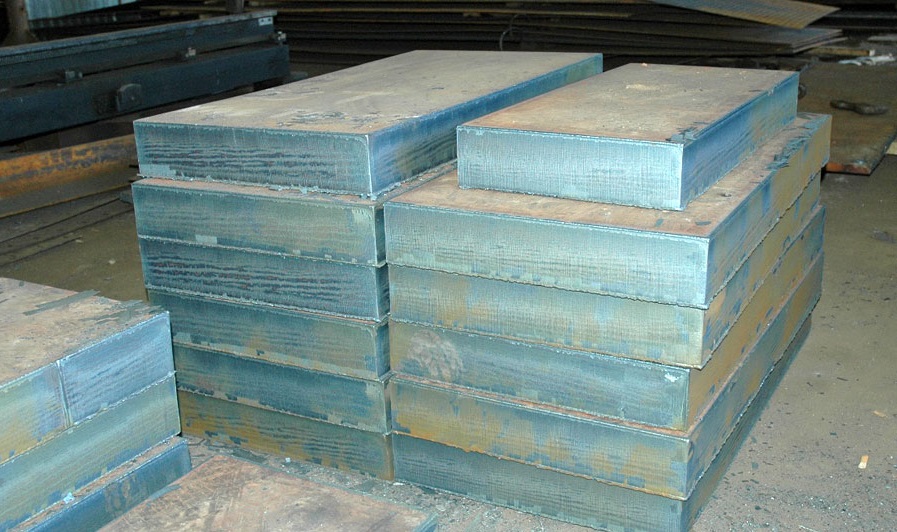

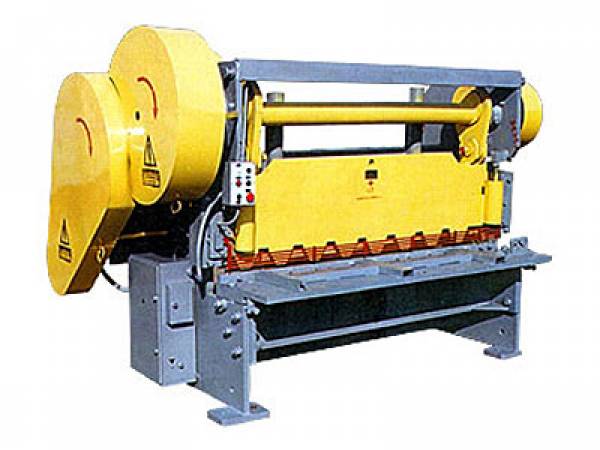

CUTTING

Maximum cutting thickness of sheet metal:

- guillotine shears for felling of sheet material with thickness from 1 mm to 30 mm and a maximum length range of up to 3000mm;

- plasma up to 80 mm. - plasma system with software control for cutting workpieces of complex configuration of high-alloy and carbon steels and nonferrous metals;

- gas cutting up to 250 mm;

- automatic gas cutting up to 250mm. - gas-cutting installation with computer control for measuring of cutting workpieces of complex configurations from carbon steel;

- band sawing machines with the possibility of cutting a rolled profile at an angle of 30-60°.